The highest four Functions YOUR LASER Reducing Support VENDO

Wiki Article

Laser slicing can be a producing approach made use of to make personalized designs and designs with the usage of a superior-run laser beam. Laser cutting is usually Utilized in the automotive, musical instrument and medical device industries because it is suited to a variety of resources, which include metal, plastic, wood, glass, paper and gemstones, to generate intricate, specific and complicated parts.

To make these parts, laser slicing support distributors use among a few differing types of laser reducing: fusion reducing, oxidation reducing or scribing. Each and every method commonly provides fewer contamination, physical problems and squander, which contributes to substance Value cost savings for your producer.

This blog put up is intended to help you gain a better idea of the laser reducing procedure so that you are nicely educated in picking the proper laser cutting services seller.

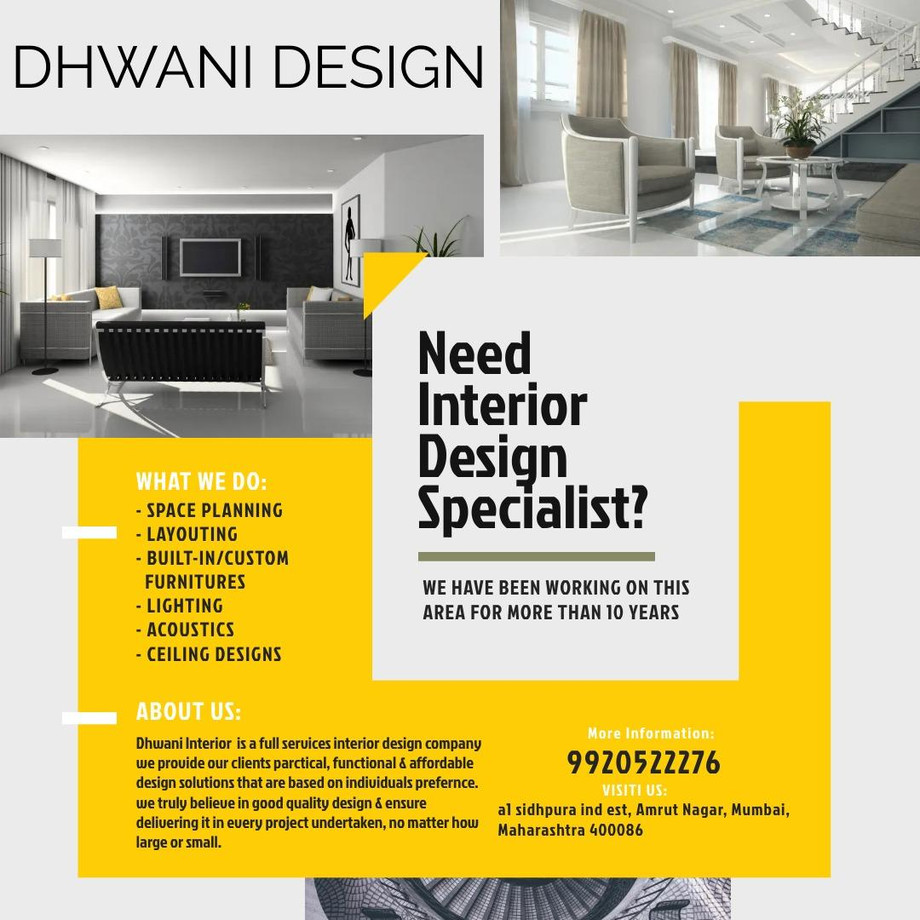

best Laser Cutting Service Provider in Mumbai Dhwani Design

The Laser Slicing Approach and Machinery

Laser chopping is often a thermal-based mostly, non-Speak to fabrication method suitable for chopping metal and non-metallic components. In contrast to mechanical chopping, which utilizes ability-driven slicing gear, laser slicing makes use of a laser slicing machine to create cuts, markings and engravings.

The Laser Chopping Method

Basic laser reducing contains the the subsequent stages:

Beam generation: The laser beam is generated through spontaneous or stimulated emission.

Beam focusing: The beam enters throughout the nozzle that directs the world of impact.

Localized heating and melting: The beam is absorbed by the material that increases in internal Strength and heat era.

Substance ejection: As part of the heating and melting procedure, areas of the material are vaporized to provide the desired cut.

Beam motion: Motion and slicing are realized by reflective mirrors, laser head motion or workpiece manipulation.

Just about every phase is vital on the laser reducing procedure and creating a specific Slice. Depending upon the product and sort of Reduce, laser chopping also employs inert or Energetic assist gasses.

Types of Laser Slicing Machines

Whilst laser reducing equipment differ in refined methods from one design to another, a laser reducing equipment is typically build to include a laser resonator assembly, mirrors and also a laser cutting head, which is made up of a laser concentrating lens, a nozzle as well as a pressurized gasoline assembly.

The differing types of laser cutting devices are categorized into gasoline, liquid and solid-state lasers. The leading two types of lasers employed by laser machines are CO2 and reliable-condition lasers:

CO2 lasers: These are used to Lower non-steel resources. Whilst laser engineering has developed to permit CO2 lasers to cut metal, they remain better fitted to slicing by products such as rubber, leather-based or wood.

Sound-state lasers: These are generally comprised of crystal or fiber that allow for for prime-powered metallic slicing. Crystal lasers are amazingly flexible in conditions of material cutting abilities. Even so, they tend to be dearer and have shorter lifespans. Alternatively, fiber lasers are cheaper and for a longer period lasting.

When researching a laser slicing service vendor, ensure to determine what sort of laser machines they have got in their machinery set. As you can see, There are a variety of various equipment which are additional suitable for distinct jobs, instead of all producers have every bit of machinery offered.

The advantages of Laser Cutting

Laser reducing gives various pros—including flexibility, repeatability, Price-usefulness and speed—in the production means of exact, substantial-good quality and adaptable components. By employing most effective techniques, your laser reducing services seller need to offer the subsequent characteristics:

a. Cutting Precision and Precision

As opposed to most conventional slicing equipment, laser reducing equipment create a variety of cuts and patterns which provide far more precision and precision. Laser cutting devices are usually entirely CNC managed, which means that they've got superior repeatability in generating complete, intricate elements. The significant-quality cuts produced by lasers typically will not need additional cleaning, treating or finishing, which decreases the necessity for secondary procedures.

b. Fewer Material Contamination and Squander

Because lasers use a concentrated beam which allows for narrower kerf widths, the level of substance taken off is minimized. With small thermal input from localized heating, the warmth-afflicted zones are minimized, which also decreases the thermal distortion. If thermal temperatures are far too significant, the material may be broken, rendering the ingredient ineffective.

c. Reduced Maintenance and Maintenance Expenditures

In comparison with other chopping devices, maintenance expenditures for laser reducing equipment are somewhat minimal. Plus, laser slicing equipment usually do not require shifting out separate equipment to perform diverse functions, which decreases both the products prices and lead time among procedures. At last, laser components knowledge fewer exhaustion simply because laser reducing can be a non-Call process.

d. Higher Operator Safety

Laser cutting features a reduced threat of operator injuries since it employs tiny to no mechanical components. Having a quiet Procedure, laser reducing is significantly less distracting than louder procedures. With fewer interaction With all the machine and fewer noise, the general workplace ecosystem is safer.

Select the Nicely-Geared up Laser Reducing Service Seller

By selecting Dhwani Design as your laser chopping support seller, you will have a workforce Together with the abilities and machinery to work with a variety of elements, meet advanced specifications and provide the ideal prototype persistently, punctually and inside finances. Report this wiki page